STRATHcube

STRATHcube is an ambitious student-led initiative at the University of Strathclyde, contributing to Scotland’s growing presence in space technology.

This project revolves around launching a small satellite—known as a CubeSat—with a mission to improve Space Situational Awareness, which helps monitor and protect satellites from the growing risk of space debris.

STRATHcube is also much more than just a scientific mission—it is a transformative educational opportunity for Strathclyde students, of which over 40 of which have already been involved.

STRATHcube has allowed students to gain hands-on experience in satellite design, project management, and has enabled their collaboration and networking with industry experts. The project has sparked interest in the space sector and has positioned Strathclyde as a key player in student-driven space innovation.

With the recent successful entry to the ESA: Fly Your Satellite! Design Booster program, STRATHcube has the chance to reach new heights. European Space Agency mentorship will help the team refine their design, solve key technical challenges, and elevate the project to its next level.

The STRATHcube team meet twice a week:

Monday and Thursday 5-7pm in Livingston Tower Room 511

OUR CubeSat

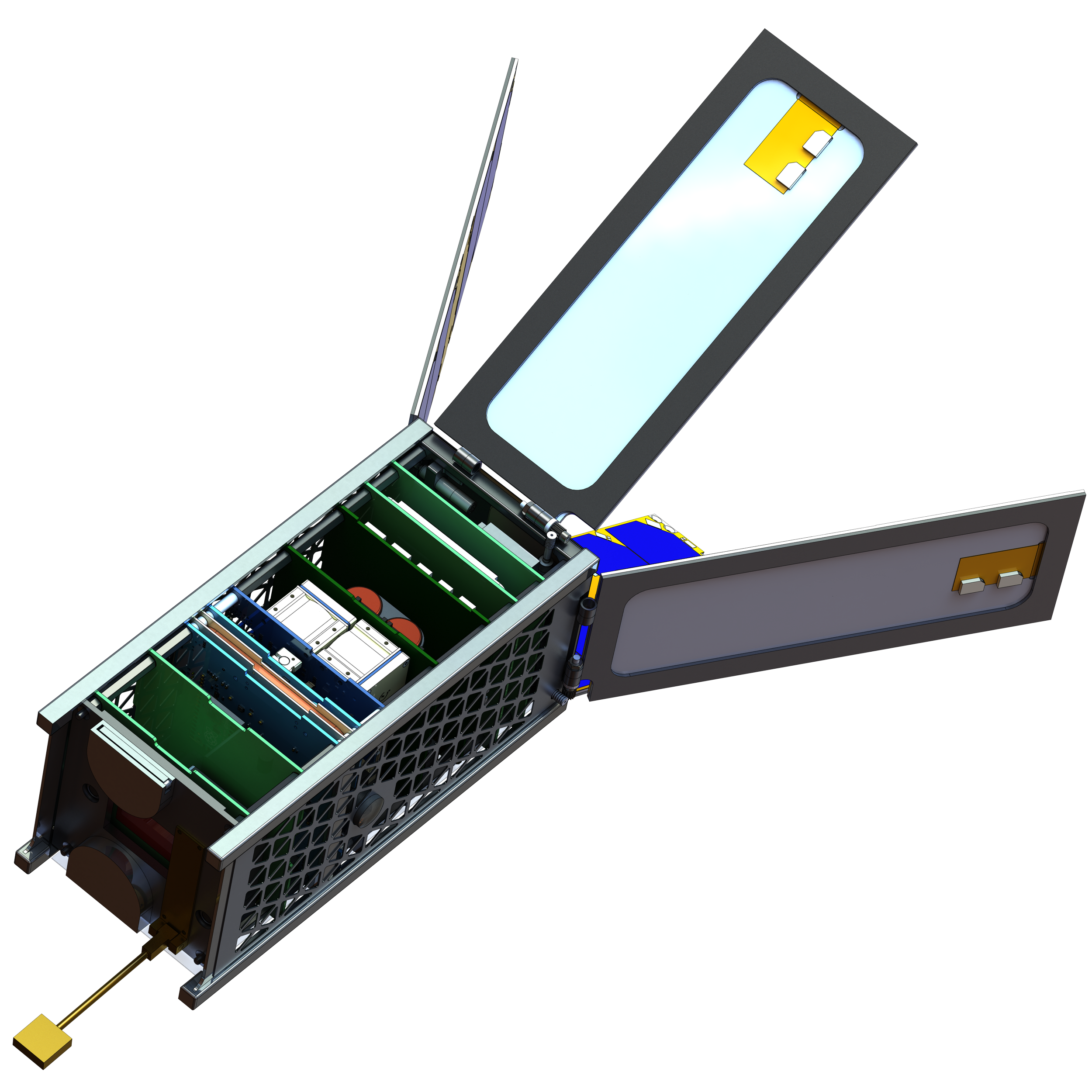

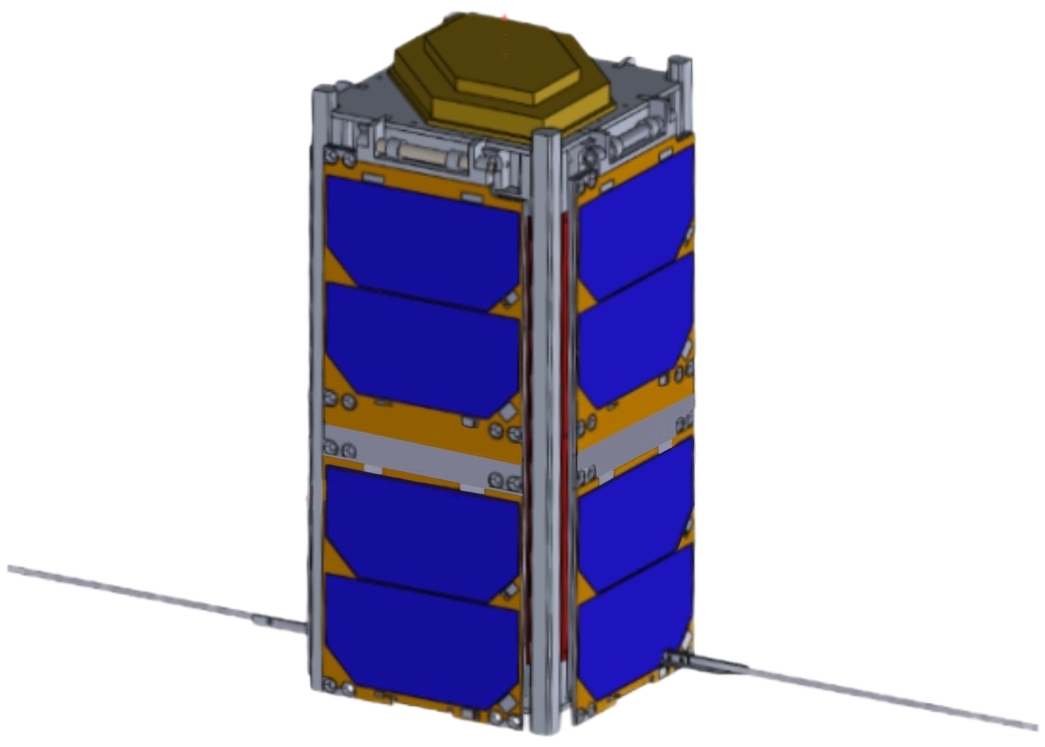

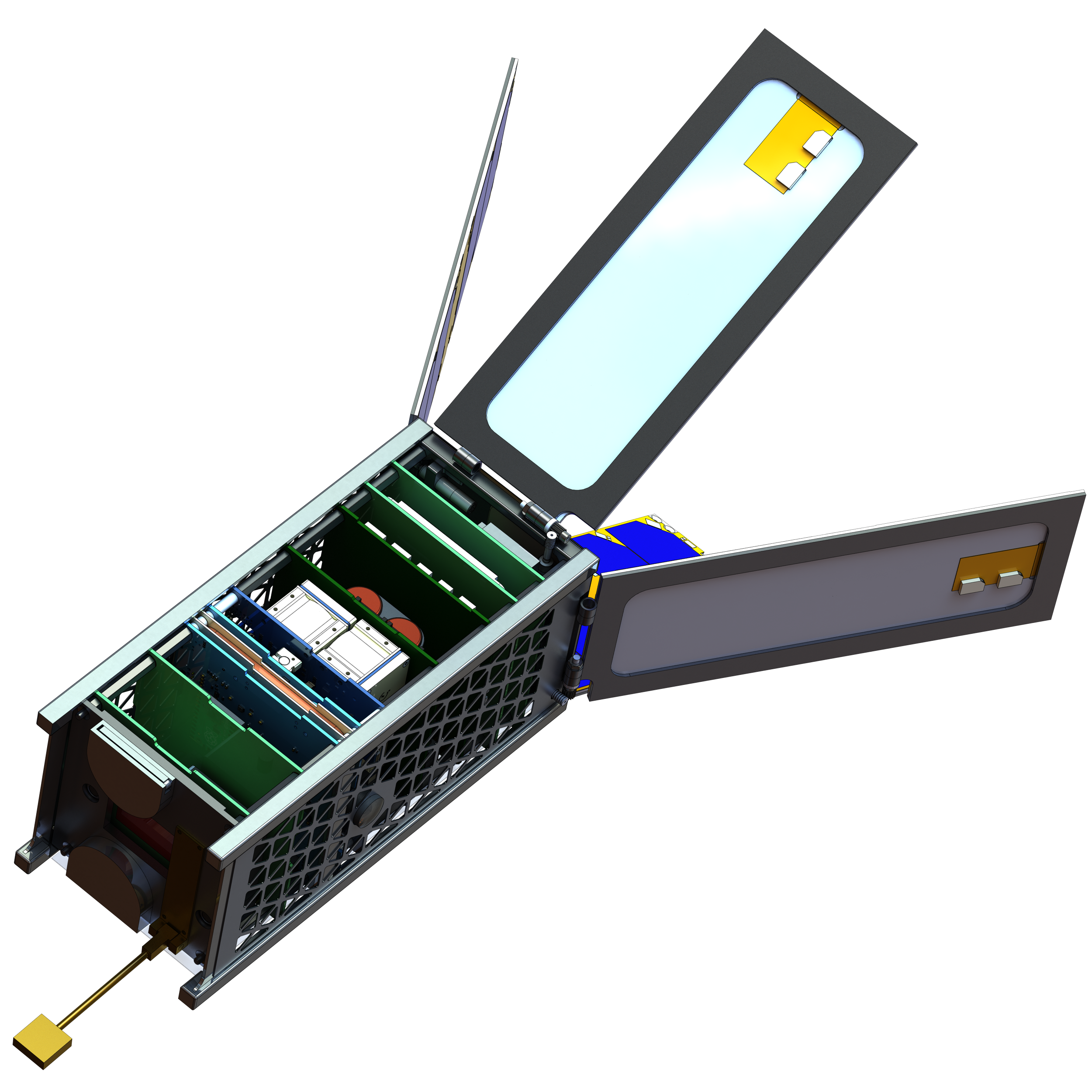

2U CubeSat

Space debris is a serious and escalating issue. With more satellites launching every year, the risk of collisions in space is rising, potentially leading to widespread disruptions in communication, navigation, and scientific research.

STRATHcube’s mission will demonstrate an innovative new approach to tracking space debris while also collecting valuable data during its atmospheric re-entry. This research has the potential to benefit the entire space industry, contributing to safer and more sustainable space operations.

STRATHcube was initially developed by master’s and bachelor’s students at Strathclyde and has expanded to involve over 30 interdisciplinary students across all academic years.

This year, a strong managerial focus has been placed on onboarding students so senior members can lead key projects and educate newcomers, preparing them to contribute directly to subsystem design and integration. A key shift is placing younger students on a multi-year track within STRATHcube.

OUR SUBSYSTEMS

Primary Payload

The primary payload is a Passive Bistatic Radar (PBR). This is a system where the radar receiver listens for signals that are already being transmitted by other sources, instead of sending out its own. In STRATHcube’s case, the CubeSat acts as the passive receiver, picking up signals from the Iridium satellite constellation after they scatter from space debris.

Implementation of PBR from orbit has significant advantages compared to ground-based radar: It avoids the signal losses caused by Earth’s atmosphere,requires lower antenna gain due to shorter propagation distances, and experiences smaller relative velocities, which makes it easier to track objects accurately by reducing Doppler shift effects. These factors enable the detection of smaller debris objects with relatively simple and low-cost hardware.

The PBR payload is central to STRATHcube’s primary mission, as it demonstrates for the first time the feasibility of detecting debris directly in orbit using Iridium transmissions. The system’s minimum detectable target size, determined by its ability to achieve sufficient signal-to-noise ratio, serves as the benchmark for success. Coupled with precise attitude and orbital analyses, this ensures the receiver is positioned at the right place and time to maximise opportunities for space debris detection.

Members working on the Primary Payload gain a solid understanding of bistatic radar theory, RF systems, and signal processing, while also developing hands-on skills in modelling, simulation, electronics, and payload testing.

Secondary Payload

The secondary payload aims to measure the aerothermodynamic and mechanical forces which lead to Solar Panel Fragmentation (SPF) during atmospheric re-entry. The data measured will be used to validate analytical re-entry simulations and analysis methods, such as TITAN which is currently being developed at the University of Strathclyde.

There are two main sections of this payload. The first is the Scientific Sensor Platform (SSP), which measures the conditions of the CubeSat during atmospheric re-entry, and the second is the Payload Support System (PSS), which ensures that the data generated by the SSP can be successfully downlinked to the ground station. Due to ionized shock waves forming around the front of the satellite at hypersonic speeds, the payload data will first be uplinked to an Iridium satellite, from which it will then be transmitted to the ground station.

As part of the PSS, the team has taken two novel initiatives to ensure the success of the re-entry experiment: 1) Passive Aerodynamic Stability by reconfiguring the solar panels into a shuttlecock formation and locating the center of pressure behind the center of gravity. This stabilizes the CubeSat’s trajectory without the need for any active stabilizer, enabling communications with an Iridium satellite. 2) A Command & Data Handling System designed for near real-time, fast, and robust data acquisition, processing, storage, and transmission.

Members working on developing this payload will enhance their knowledge of the mechanical and thermal conditions of a spacecraft and its motion history at hypersonic speeds, gain experience with re-entry simulation tools such as TITAN through close collaboration with researchers at the Aerospace Centre of Excellence, select a range of analog and digital sensors based on precise simulations and trade-off analyses, and implement the PSS.

Mission Analysis

Mission analysis is about working out how a satellite should travel through space so it can actually achieve its mission goals. This includes studying orbital mechanics, checking what parts of the Earth and sky the satellite can see, constraints from launch and deployment systems, and ensuring communication with the ground is possible. In short, mission analysis builds the “flight plan” that makes the mission realistic and achievable.

For STRATHcube, mission analysis is especially important because both the primary and secondary missions depend on stability. The primary mission - detecting debris using the Passive Bistatic Radar system - relies on a stable orbit so signals from the Iridium constellation can be detected accurately. The secondary mission is different: instead of orbiting, the satellite will follow an uncontrolled re-entry trajectory. In this case, mission analysis makes sure the trajectory is stable enough through Passive Aerodynamic Stability to keep transmitting data back through Iridium as the CubeSat descends.

What makes STRATHcube unique is how both missions are considered together. Instead of just planning for orbital coverage, the analysis also has to account for aerodynamic stability during re-entry. By combining orbital design with trajectory planning, STRATHcube ties both missions into one unified dual-purpose framework.

In this subsystem, students build a strong foundation in orbital and trajectory mechanics, coverage analysis, ground station access, and launch and deployment constraints. Alongside this theory, they gain hands-on experience with simulation tools, data analysis, and trade-off studies, while working closely with other subsystems to design realistic mission profiles.

Command & Data Handling

The Command & Data Handling (C&DH) subsystem is responsible for sampling, transferring, processing, and storing data and commands within the satellite. It can be considered the “brain” of the satellite, making decisions based on pre-defined software, information received from other subsystems, and telecommands from the ground station, and executing the corresponding actions.

The main component of C&DH is the On-Board Computer (OBC). Like a traditional desktop computer, the OBC performs a range of tasks including housekeeping and satellite health monitoring, fault detection and recovery, telemetry management, application execution, and data processing. STRATHcube’s OBCs run on a Real-Time Operating System (RTOS), enabling time-sensitive task execution and fully autonomous operations, which are especially critical during the secondary mission phase when there is no communication with the ground station.

Failure of the C&DH subsystem would jeopardise the entire mission. Therefore, in addition to its standard functions, the system must be highly tolerant to environmental conditions encountered in space and earth's thermosphere. The C&DH subsystem provides an excellent learning opportunity for team members to gain experience in embedded development, software design under constraints, and the testing and verification required to ensure a successful space mission.

Attitude Determination & Control System

The Attitude Determination & Control System (ADCS) is divided into two closely related functions: determination and control. The determination function typically uses sensors to monitor the space environment and algorithms to process this data, providing an attitude estimate of the CubeSat. The control function takes this attitude estimate together with a desired pointing direction, processes them through a control algorithm, and calculates the necessary adjustments. These commands are passed to the actuators, and the cycle repeats in a feedback loop until the desired stability - within an acceptable margin of error - is achieved.

For STRATHcube, attitude determination and control are essential to ensure reliable reception of Iridium satellite signals, detection of space debris, efficient power generation from the solar panels, and communication with the ground station. This is achieved during the primary mission using three reaction wheels, which generate torque and conserve angular momentum along all three axes. However, during atmospheric re-entry, excessive aerodynamic forces prevent this system from functioning effectively. For the secondary mission, a passive stabilisation method known as Passive Aerodynamic Stability is employed instead.

The ADCS subsystem provides valuable learning opportunities for members, including orbital mechanics and dynamics, line-of-sight coverage analysis, control systems, and sensor integration.

EPS

The Electrical Power System (EPS) is a critical part of any engineered platform, responsible for generating, storing, regulating, and distributing energy to ensure that all subsystems operate reliably and efficiently. It encompasses energy harvesting, typically through solar panels, storage in batteries, and the regulation and distribution of power to different loads at the correct voltage and current levels. In short, the EPS is the "circulatory system" of any technological platform.

In STRATHcube, the EPS is even more vital due to the severe limitations in size, surface area, and storage capacity. Every watt of energy must be carefully managed to guarantee mission success. The EPS ensures that the satellite can not only harvest and store energy effectively while in sunlight, but also survive extended eclipse periods by supplying stored power to the most critical functions. It also enables intelligent prioritisation of power allocation to different subsystems and payloads, ensuring that communications, data handling, and attitude control remain operational even under constrained energy budgets. Without a reliable EPS, no other subsystem on a CubeSat can function properly.

In the STRATHcube design, the EPS uses solar panels for power generation and batteries for energy storage, distributing and supplying power to all subsystems as required. This setup ensures reliable energy provision throughout the mission, with guaranteed power support for two separate payloads as well as the satellite’s remaining core subsystems. By combining efficiency, stability, and flexibility, STRATHcube’s EPS demonstrates distinctive design strengths and engineering maturity that set it apart. Members of this sub-team learn the fundamentals of solar power harvesting, battery storage behaviour, and power regulation strategies, along with the challenges of managing strict power budgets in CubeSats.

Structures & Mechanisms

The Structures & Mechanisms sub-team is responsible for designing a strong yet lightweight frame that can withstand launch forces and vibrational frequencies, while protecting the satellite’s internal components to ensure they operate as planned. This requires careful material selection, innovative CAD design, forward thinking, and extensive finite element analysis (FEA) to determine modal frequencies, assess structural response to random vibrations, and ensure the load-bearing rails can withstand the high G-forces of launch. STRATHcube’s structure is also designed to safeguard internal components and sensors during re-entry, allowing the secondary payload to operate up to the point of demise.

Additionally, strict dimensional requirements must be met to comply with CubeSat and ESA standards, and the structures team must integrate these alongside individual component requirements. On the mechanisms side, the sub-team focuses on creating simple, reliable designs with built-in redundancies to actuate key components such as the solar arrays and deployable antennas, minimising the risk of failure.

This involves applying fundamental engineering principles to design hinges, separation springs, and hold-down and release mechanisms. Preliminary designs are visualised in CAD to simplify the mechanisms and ensure proper integration with the structure. FEA simulations are then used to predict performance before moving to manufacturing and testing. Reliable mechanisms will enable STRATHcube to reconfigure its solar panels from the stowed configuration (for launch and primary mission phases) to the shuttlecock configuration (for the secondary phase) and ensure successful communication with the ground station through the deployable antennas. STRATHcube’s structure and solar array hinge will be manufactured and tested in house by the structures and mechanisms team.

Thermal

The thermal subsystem is responsible for keeping all spacecraft components within their allowable temperature ranges throughout the mission. In orbit, the satellite alternates between periods of direct sunlight and eclipse, creating significant temperature fluctuations. During atmospheric re-entry, it is exposed to far harsher heating conditions driven by altitude, velocity, and position. To ensure reliability, it is essential to simulate and analyse the thermal environment of both the spacecraft as a whole and of critical internal components, then design and implement an appropriate thermal control system.

A thermal control system must maintain component temperatures within operational limits during normal conditions and within survival limits during extreme cases, ensuring that no subsystem loses functionality. It should also reduce temperature gradients across the spacecraft, particularly in sensitive components such as optical elements.

What makes STRATHcube’s thermal design unique is that it must account for two very different environments: low Earth orbit and atmospheric re-entry. This dual requirement means the thermal control system must keep the spacecraft operational from deployment into orbit through to the end of its controlled re-entry experiment, ensuring mission success across both regimes.

Our team is fortunate to have access to ESATAN, an advanced thermal analysis software widely used in the space industry. This tool allows us to build detailed models of the spacecraft and accurately predict its thermal performance across all phases of the mission. By using ESATAN, we can assess the impact of sunlight and eclipse in orbit, as well as the extreme heating during atmospheric re-entry, ensuring that our thermal control strategies are robust and effective throughout the satellite’s entire life cycle.

Members in the Thermal sub-team develop a grounding in heat transfer theory in space and the atmosphere, along with an understanding of how the satellite and its components are affected by extreme temperature changes during both orbit and atmospheric re-entry. They gain hands-on experience modelling and simulating these environments, and learn to design thermal control systems that keep components within their operational and survival limits.

AIV

Assembly, Integration, and Verification (AIV) is the critical process of physically and functionally combining individual satellite components (Assembly) into a functional system, then combining these subsystems to ensure they operate correctly as a whole (Integration), all while confirming through objective evidence that the system meets its specified requirements (Verification). For a CubeSat, this process is vital to improve its inherently low reliability, which is often sacrificed for low cost and fast delivery through the use of commercial-off-the-shelf (COTS) components not designed for space. The responsibilities of AIV are to detect and correct defects in design, material, and workmanship through rigorous testing before launch, thereby reducing the high rate of failures in orbit and ensuring the satellite can survive the launch environment and successfully perform its mission.

The STRATHcube project utilises a unique combination of COTS and custom-designed components, necessitating a tailored AIV strategy and framework to ensure the successful operation of this exclusive integrated system. Thanks to the support of the Department of Mechanical & Aerospace Engineering, the STRATHcube team has access to a dedicated cleanroom facility for the assembly, integration, and testing of components sensitive to contamination. Conducting these critical AIV activities in a controlled cleanroom environment is essential for the project to comply with the stringent ECSS and ESA standards required for launch approval and mission success.

By participating in the AIV sub-team, members will gain invaluable theoretical knowledge and practical hands-on skills that are highly sought after in the aerospace industry. Theoretically, they will learn systems engineering principles, the logic behind international testing standards like ISO-19683 and ECSS, and the physics of the space environment (including thermal, vacuum, and vibrational stresses). Practically, they will earn direct experience in cleanroom protocols, electrostatic discharge (ESD) safety, precision mechanical assembly, and the operation of sophisticated test equipment. This includes conducting functional tests, performing vibration tests to simulate launch conditions, and potentially executing thermal vacuum tests to validate performance in a space-like environment. This end-to-end involvement in transforming a design into a flight-ready satellite provides an unparalleled education in mission assurance and hardware reliability, fostering a deep understanding of the rigorous processes required for space qualification.