ROCKETRY

The StrathAIS rocketry team is a part of Strathclyde Aerospace Innovation Society (StrathAIS), the University of Strathclyde’s largest aerospace society.

We recently took part in the 2025 International Rocket Engineering Competition (IREC), hosted in Midland Texas, USA.

This represents the pinnacle of student rocketry, being the largest intercollegiate competition of its kind in the world. In 2025, over 170 teams with 2,000 of the world’s best students competed in Texas.

With the rocketry team being created in 2021, the team has entered IREC every year since 2022, competing in the 10K COTS category each time. The rocketry team has seen a year-on-year increase in popularity with 95 members in the recent year.

The event itself is sponsored by some of the largest and most influential companies in the Aerospace sector, such as Blue Origin, NASA, SpaceX and ProtoSpace MFG.

Following a nominal flight at IREC 2024, the team decided to step up to the 30K COTS category for the first time.

OUR ROCKETS

OUR LATEST, “TARANIS“

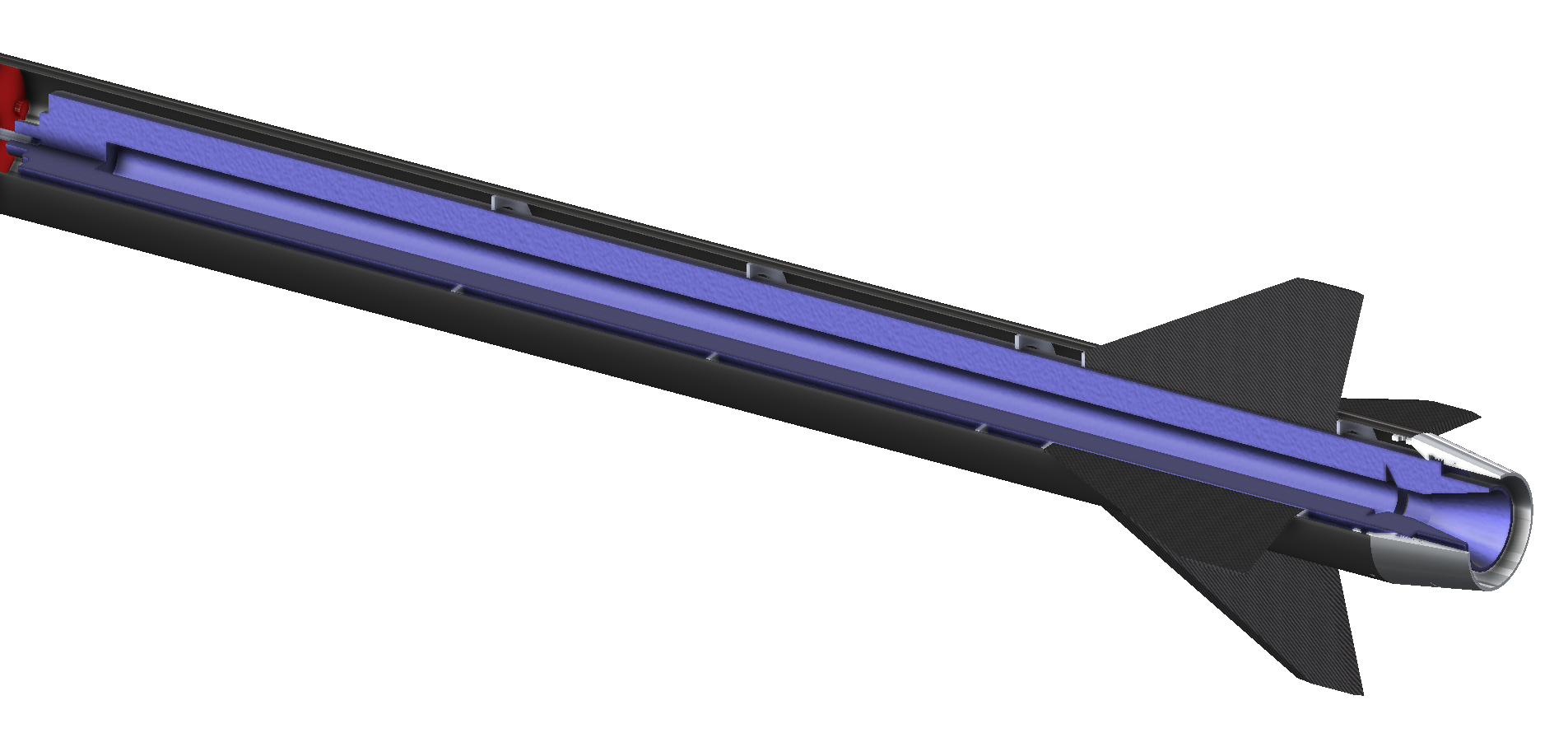

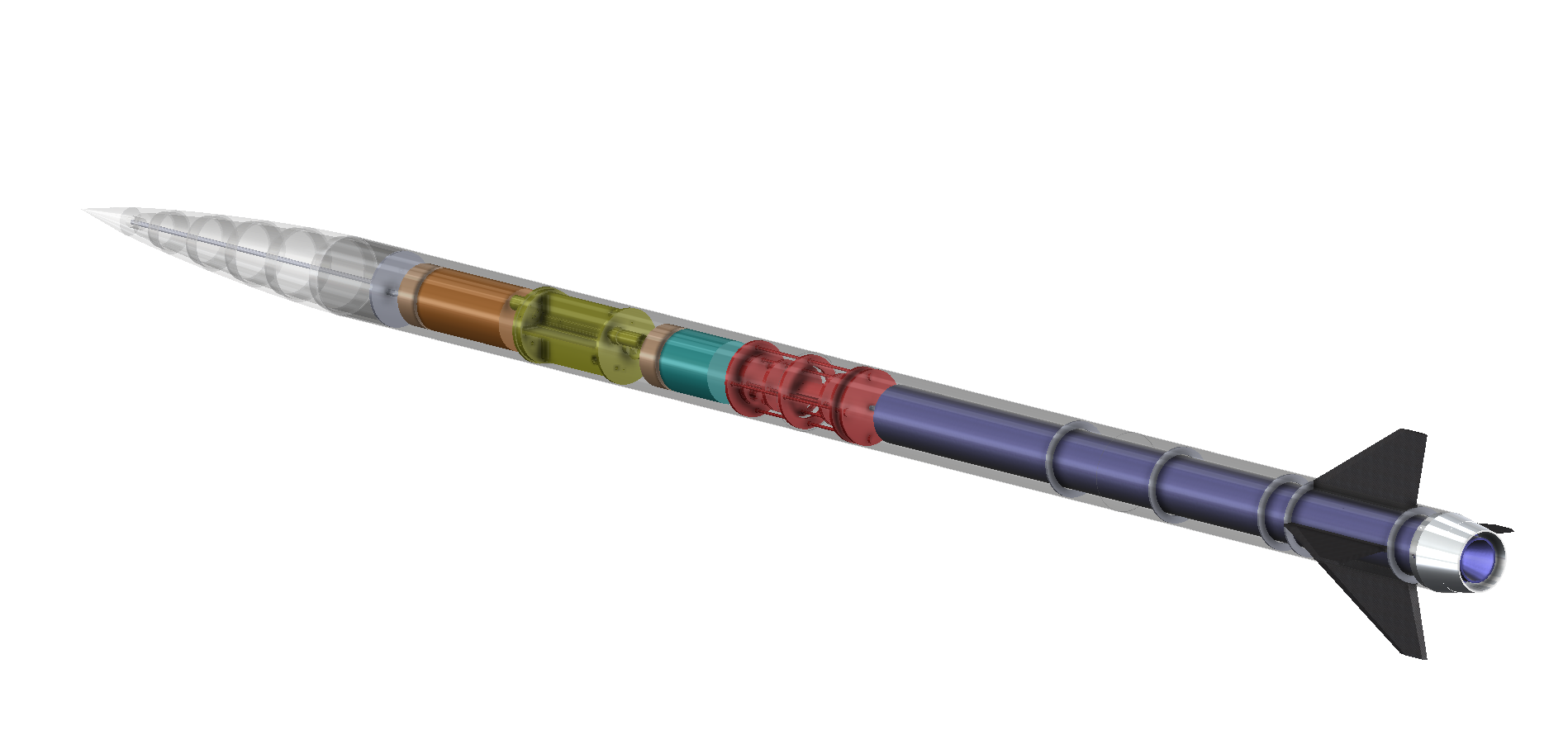

Due to entering IREC 2025 with “Taranis“ into a higher category for the first time, the design is very different to previous entries while continuing to build on lessons learned over the years.

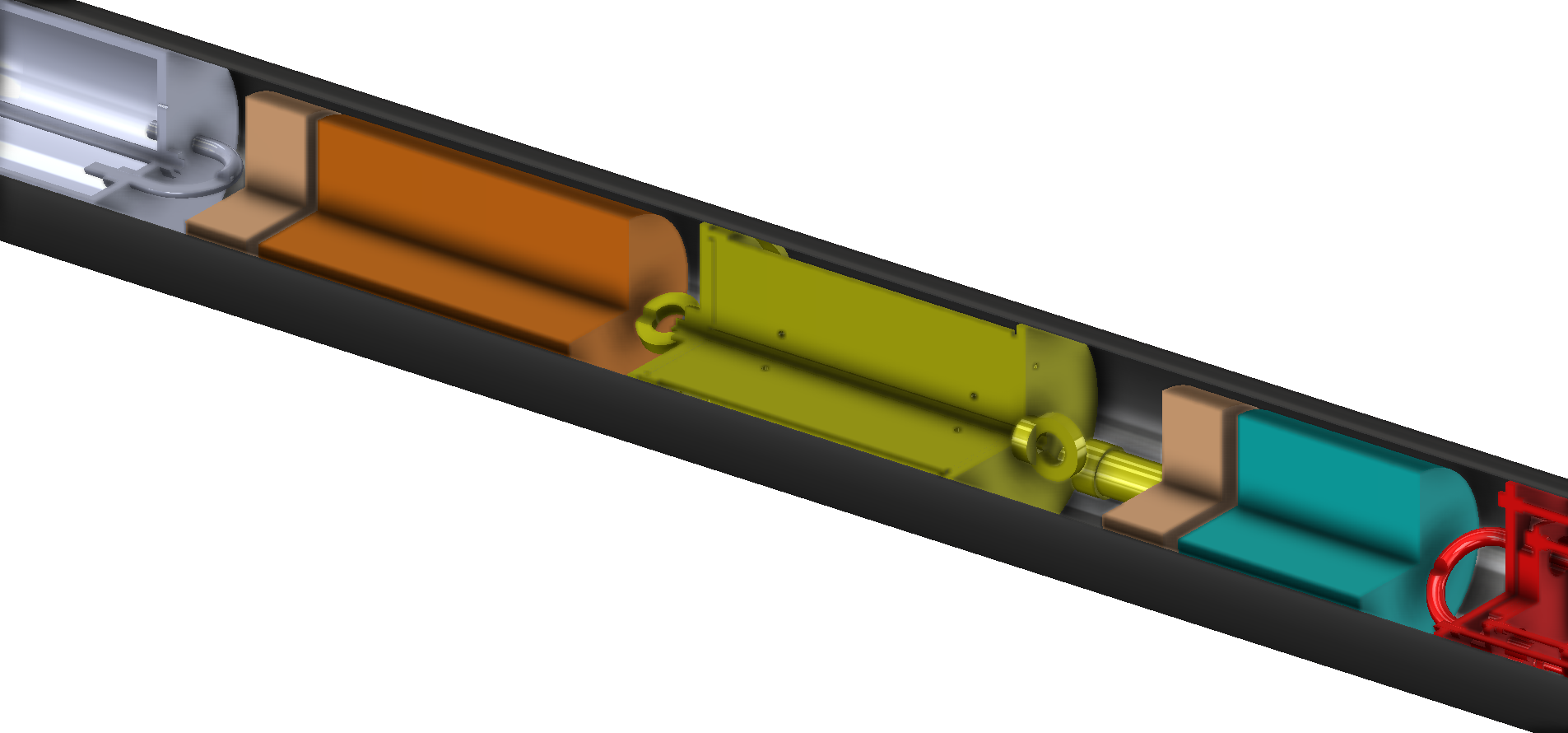

Taranis is composed of four primary subsystems: Structures, Propulsion & Recovery, Payload, and Avionics. The rocket featured an SRAD flight computer and GPS built by the avionics team, a scientific payload that aimed to gather in-flight data to allow for more informed design choices for further years, an aluminium boat tail for improved aerodynamic performance and was flown on an Aerotech O5500 motor.

Unfortunately, due to a CATO caused by a motor malfunction, we were ineligible to receive points from our flight performance score .

Overall, we placed 102nd out of the 159 teams that competed and 12th out of 21 in our category (30K COTS), a great achievement for our first attempt! For our technical report, we scored 191/200. This placed us 2nd in our category, and 6th overall in the competition, a testament to the hard work and discipline from the team throughout the year.

ROCKET CHARACTERISTICS

HEIGHT

DIAMETER

APOGEE

MACH NO.

MAX VELOCITY

MAX ACCELERATION

TOTAL MASS

TOTAL FLIGHT TIME

STABILITY

3.51 m | 11.5 ft

133 mm | 5.24 in

9,690 m | 31,791 ft

1.77

608 m/s | 1360 mph

238 m/s2 | 780.8 ft/s2

34.9 kg | 76.9 lbs

400 s

2.78 cal

FEATURES

-

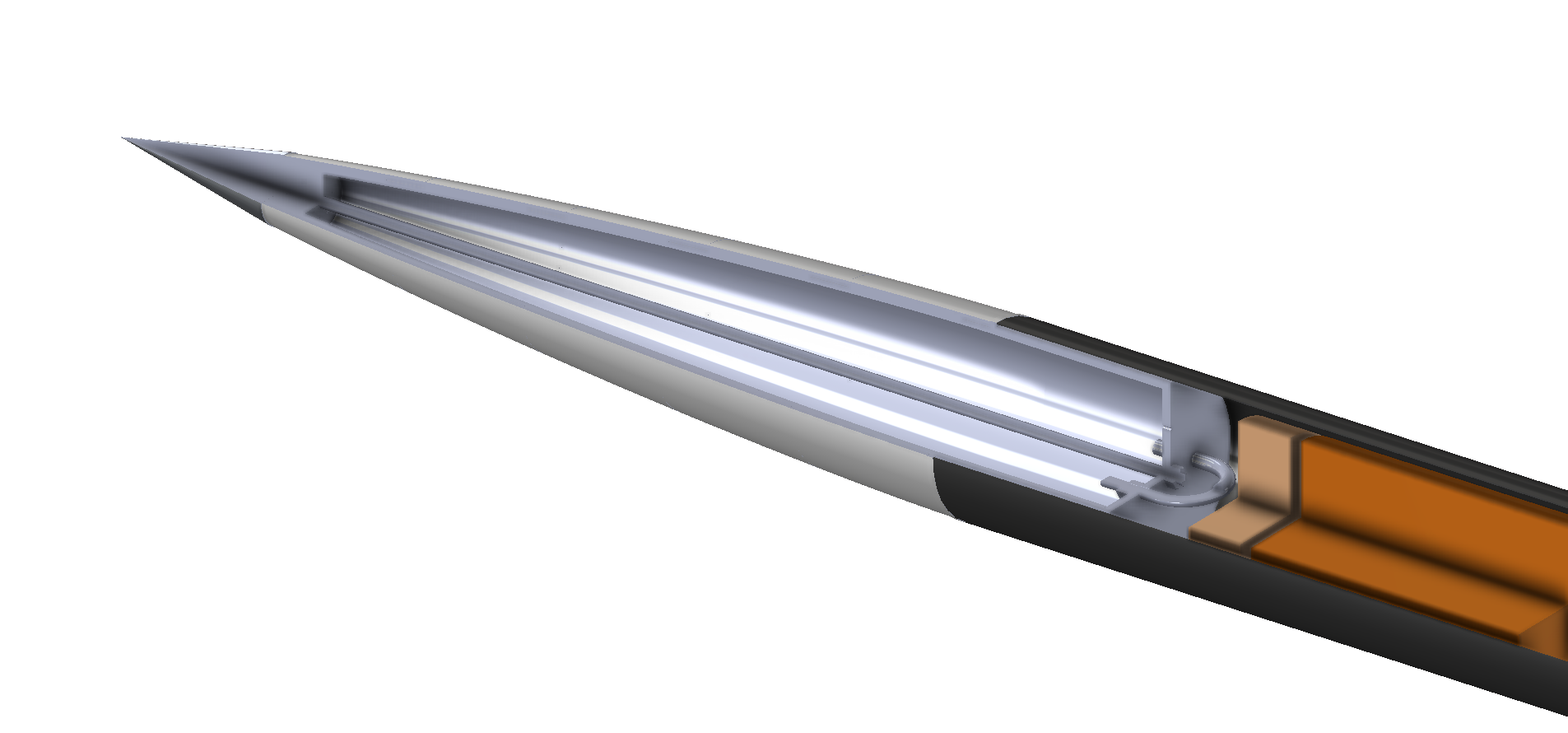

3D PRINTED ONYX NOSECONE REINFORCED WITH A CARBON FIBRE SKIN

IN-HOUSE MANUFACTURED 5 LAYER FIBREGLASS AIRFRAME

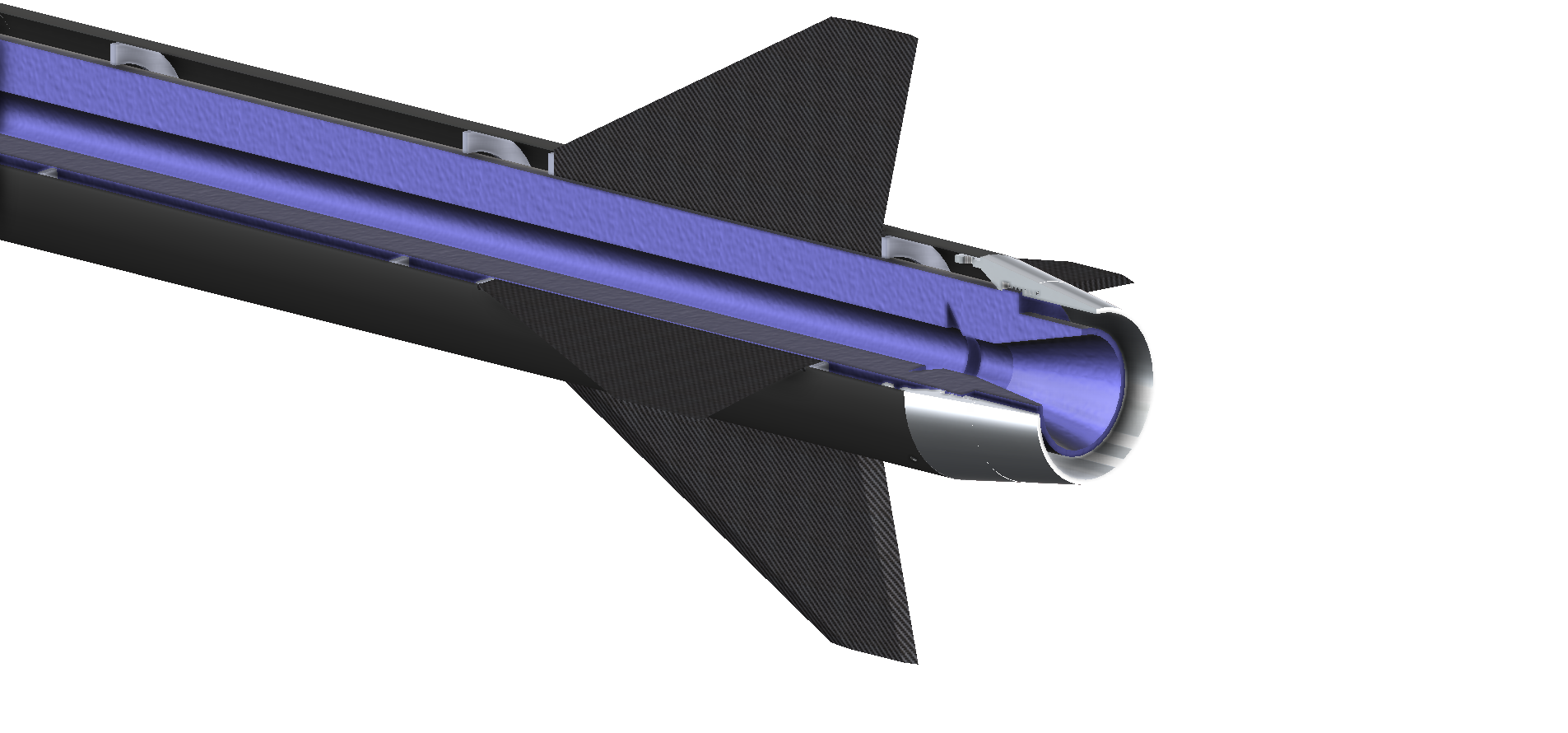

4 TAPERED SWEPT CARBON FIBRE FINS

AERODYNAMIC ALUMINIUM BOAT TAIL REDUCING BASE DRAG

-

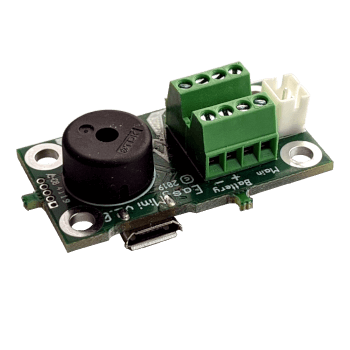

AVIONICS 4 BAY DESIGN HOLDING SRAD FLIGHT COMPUTER AND EASYMINI COTS FC

-

10ft MAIN HIGH DRAG TOROIDAL ANNULAR PARACHUTE

4ft DROUGE PARACHUTE

O5500X-PS ROCKET MOTOR | TOTAL IMPULSE OF 21,348Ns

-

2KG FUNCTIONAL NON-DEPLOYABLE SCIENTIFIC PAYLOAD HOLDING VARIOUS FLIGHT SENSORS

PREVIOUS ROCKETS

MK. III

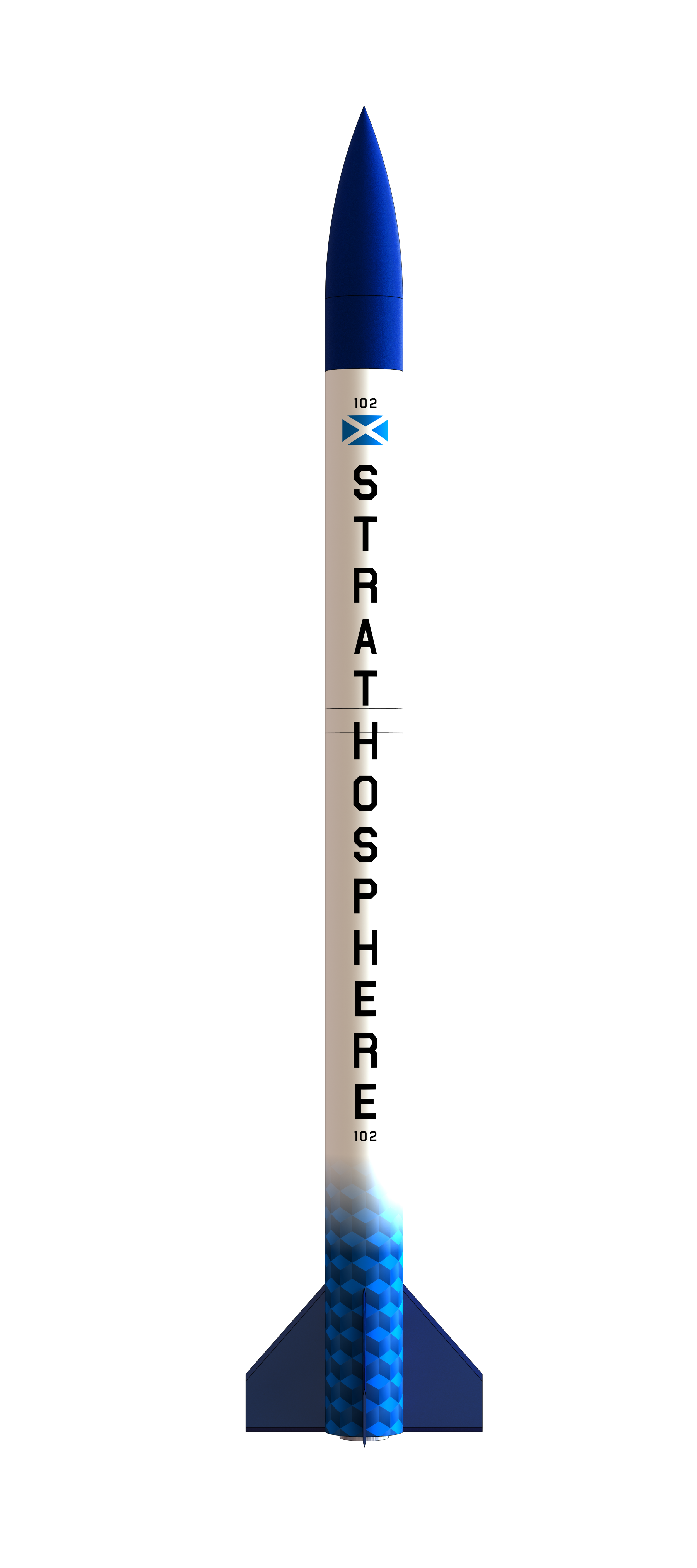

The Mk. III was the last of the “STRATHOSPHERE“ family, first starting development in 2023 after another successful year at the Spaceport America Cup using the Mk. II.

Carrying the momentum forward, the Mk. III was entered into the 10K COTS category of the 2024 IREC Spaceport America Cup which resulted in the best result the Rocketry Team has seen, placing 9th in our category!

MK. II

Our second rocket in the Level 3 Strathosphere family, the MK II first started development in 2021 after our first year at the Spaceport America Cup.

The MK II was entered into the same 10K COTS category of the 2023 IREC Spaceport America Cup which achieved great results from the previous year.

MK. I

Our first rocket in the Level 3 Strathosphere family, the MK I was a major milestone after years of planning and research consisting of only 19 members.

Entering for the first time into the 10K COTS category of the 2022 IREC Spaceport America Cup our team managed a successful launch and recovery. Marking a huge milestone in the teams history.

OUR SUBTEAMS

STRUCTURES

The structures sub-team will research and design the overall geometry of the rocket, ensuring that the design is manufacturable, will withstand expected flight conditions and provide the required flight characteristics.

The team will produce a CAD model of the full rocket and complete a range of simulations to validate the design. This includes aerodynamic simulations, fin-flutter analysis, FEA and CFD. The team will implement lessons learned from previous years, aiming to reduce the complexity of pre-flight assembly during the competition.

The team will communicate effectively with other sub-teams throughout the design process to ensure that the rocket structure does not impede or restrict their designs.

AVIONICS

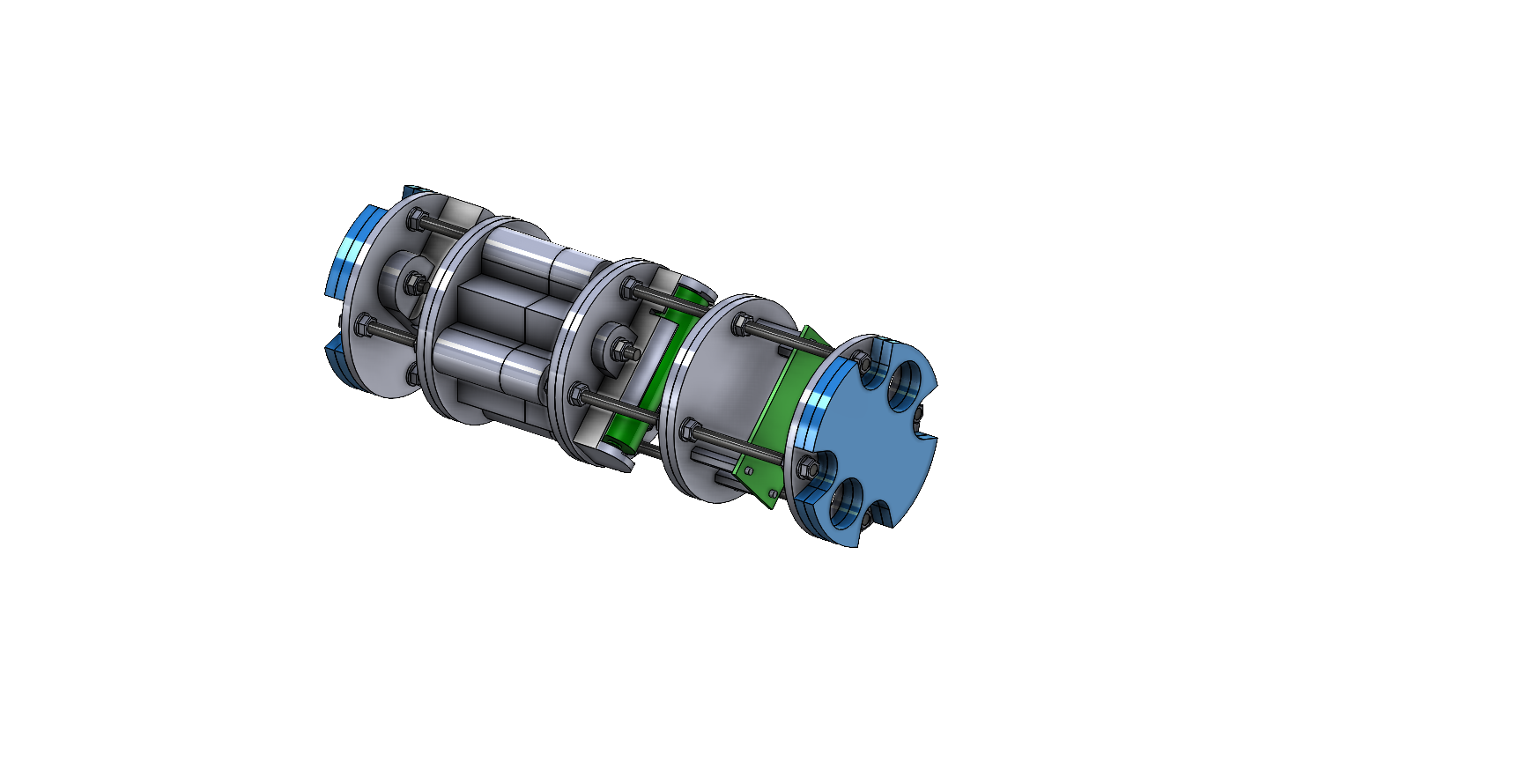

In the avionics sub team we handle the majority of the electronics for the rocket, which includes flight computers, radios, GPS's and appropriate ground stations. The main focus of the sub team is the creation and development of these systems.

Last year we created our first dedicated flight computer and radio, both of which will be improved upon this year taking what we learned last year and building new ones from the ground up. Redoing component selection, board design and programming of both.

Initial development began on a GPS however it didn't get far and we expect it to be multiple years before a complete version is produced. Additionally, this year we intend on creating a telemetry visualisation system, a more programming based project that will take the telemetry data sent to the ground station by the flight computer and display it in a way that is more understandable at a glance.

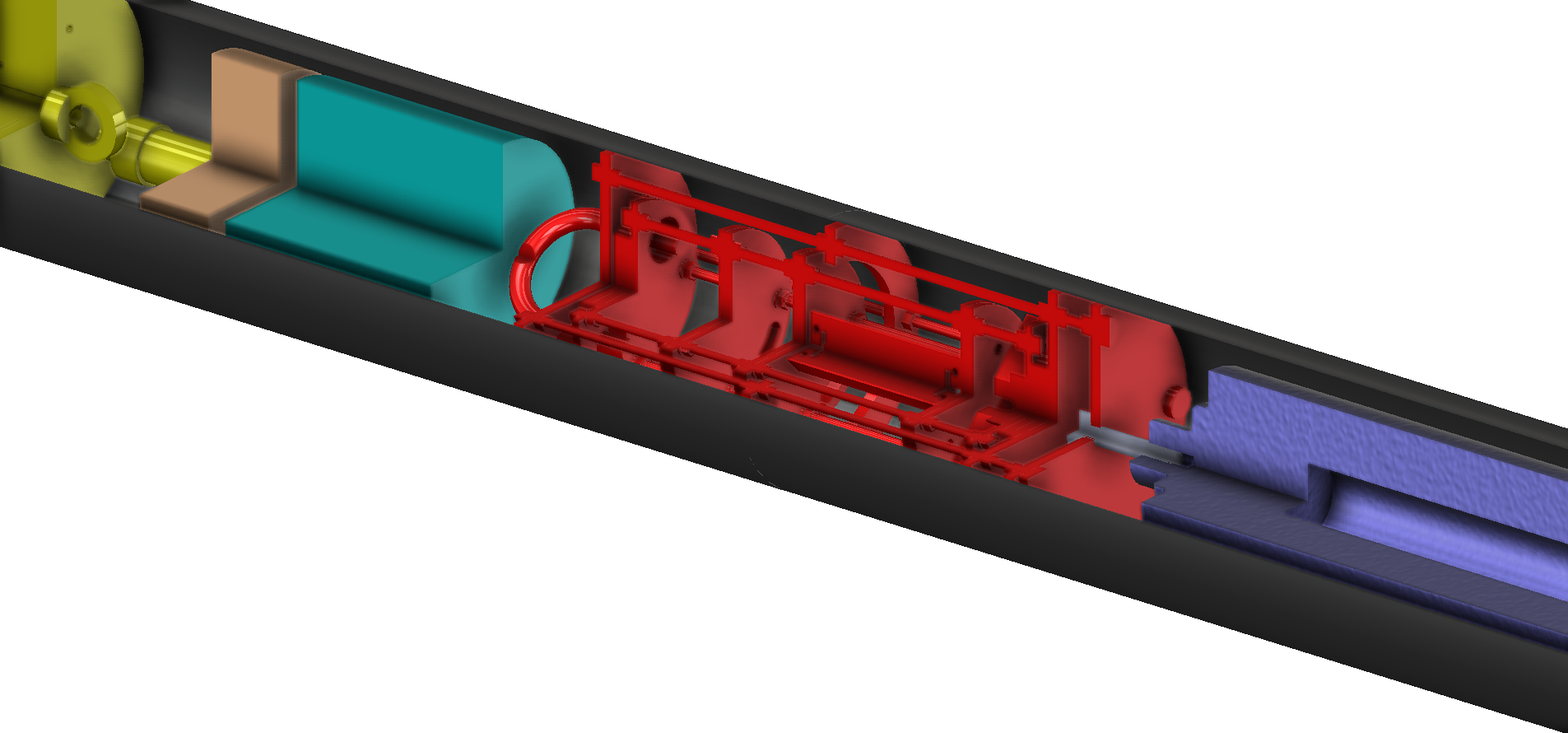

RECOVERY & PROPULSION

The Recovery team is responsible for ensuring that the rocket returns back to the group undamaged. The system employed for Mk.IV (Taranis) is similar to that of Mk.III, which is a dual-deployment system. An initial drogue parachute deploys at apogee, later followed by a larger main parachute which slows the rocket down to a safe velocity before making contact with the ground.

Both parachutes use a black-powder ejection system, which pressurises the internals of the airframe and forces separation. Each section of the rocket is connected to each other by Kevlar cords to ensure that it remains in one piece for collection once on the ground.

The choice of motor plays an important role in the overall design of a rocket, especially rockets that have a target apogee as high as 30,000ft. As the team currently competes in the COTS (commercial-off-the-shelf) category for motors, we have to purchase one.

The team currently uses the Aerotech O5500X-PS (solid-propellant), which provides around 7.5kN peak thrust.

PAYLOAD

The payload sub-team is responsible for designing, manufacturing, testing and finally operating a functional scientific experiment of our choosing. This is to be placed within the rocket and used during its flight.

The extreme conditions of rocket flight create a unique and exciting environment in which we can perform a range of tests to gather useful data on our chosen subject area. The experiment and payload will be entered into the SDL Payload Challenge at IREC where our design will be evaluated and scored along with the launch of the rocket.

LOCAL LAUNCHES

View some of our level 1 and 2 rockets launched locally in Scotland, Fairlie. These launches give an opportunity for new and existing members to gain experience in launching model rockets, building confidence and skills for our level 3 rocket launches.

Hosted by the Scottish Aeronautics & Rocketry Association (SARA), a United Kingdom Rocketry Association (UKRA) affiliated club for model, high-power, and amateur rocketry in Scotland.